HSS Tools

HSS Tools

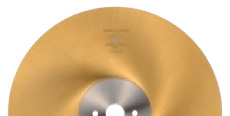

TiN

Only a few microns thick, the PVD coating increases surface hardness and, along with the low friction coefficient, prevents built up edge. Also, the feed speed can be improved by about 50% compared to non-coated products, thanks to the high thermal resistance. As a result, cutting time is reduced, the saw needs to be replaced less often, and its life is also lengthened.

-

♦ PVD coated

♦ Surface handness : HV 2200 - 2400

♦ Oxidizing temperature : 600?

♦ Friction coefficient : 0.55

♦ Application : Mild steel, Medium hardness steel

TiAlN

This blade is optimal for cutting high-tensile steel material or stainless steel. Thanks to the high thermal resistance and low friction coefficient, high-speed dry cutting is supported.

-

♦ PVD coated

♦ Surface handness : HV3300 - 3500

♦ Oxidizing temperature : 800?

♦ Friction coefficient : 0.60

♦ Application : High hardness steel, Stainless steel, titanium steel

CrN

The advantages of this PVD coating are coat thickness, high surface hardness, and a low friction coefficient. This saw is optimal for cutting sticky materials where gumming happens easy, such as non-ferrous metals.

-

♦ PVD coated

♦ Surface handness : HV2500 - 2900

♦ Oxidizing temperature : 700?

♦ Friction coefficient : 0.30

♦ Application:Nonferrous metal such as Cast iron, Aluminum and Copper

OV

The entire blade is steam treated and has a black oxide (Fe3 O4) coating w?th oil-bearing properties. Use it for ordinary material cutting, except for non-ferrous metals.

-

♦ Surface handness : HV900

♦ Friction coefficient : 0.65

♦ Application:Common steel excerpt nonferrous metal

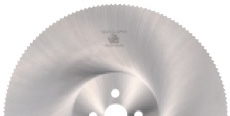

White

This blade has no surface treatment and is mainly used for cutting non-ferrous metals.

-

♦ Surface handness : HV750 - 850

♦ Application:Nonferrous metal such as Aluminum and Copper